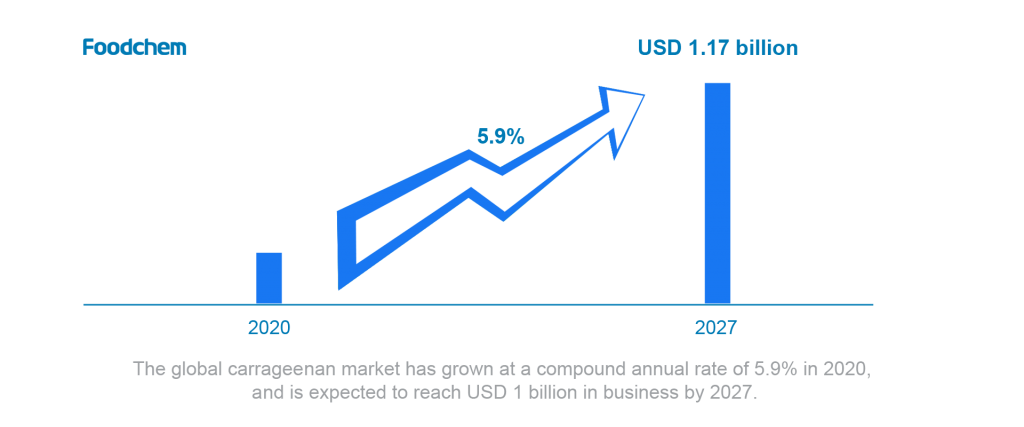

Carrageenan is one of the most important edible gel applies in food business for years. The global carrageenan market size is expanding rapidly at a CAGR of 5.9% in the past 2020 and that was the number we see under the impact of COVID-19 epidemic. It will grow to a billion-dollar business in 2027 by estimation at USD 1.17 billion. Kappa Carrageenan finds its wide application in diary and food business for its characteristic fatty mouth feel which gives varieties low fat or skim dairy products a whole flavor. Thus, Kappa Carrageenan is an inseparable ingredient in dairy and other foods especially in industrial production era.

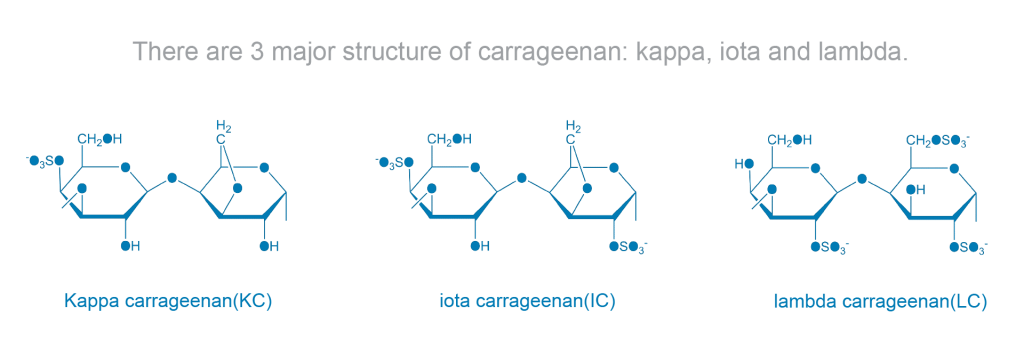

There are 3 major structure of carrageenan: kappa, iota and lambda. Each structure offers distinct functionalities.

Kappa Carrageenan presents the firmest physicality among the 3 types and often to be used in dairy and meat production process for its texture to mimic rich fat mouth feel in low fat dairy or meat products. Wherein Iota carrageenan, also known as “the elastic gel”, has a special property called “thixotropy” which is applied in food business for creating gravy like seasoning or particle suspension drinks taste like soy milk. At last, lambda carrageenan, one of the most widely used thickener in food business. This type of carrageenan creates a viscous but pseudoplastic liquids. For dairy products, syrups, beverages, sauce and dressings, lambda enables a full bodied, creamy texture.

Kappa Carrageenan is, amongst the 3 types of carrageenans, the most widely used type. Kappa Carrageenan is extracted from cottonii seaweed, a natural see plant commonly seen in South-East Asian countries. It presents the best gelling performance and soluble in hot water over 80℃. Due to such property, Kappa Carrageenan finds its best application in meat production which brings industrial level improvement of the product including but not limited to:

- - Stabilizing fat-protein emulsion for which fractions are kept together, resulting in better cut for final product.

- - Improves texture of the product & slice ability

- - Improves water containment for better mouthfeel

- - Grants better weight yield due to weight holding capability

- - Improves freeze and thaw stability of the product

Nowadays, you can find Kappa Carrageenan dominating the pre-packed meat product. Without Kappa Carrageenan, industrial meat packers will find their product softened to the level that slicing might become a problem. As to yields, it drops to the point that breaks the P&L balance which may eventually bankrupt the whole business. So, using Kappa Carrageenan or not, is no longer a choice, but a question about survival for the business. Hence, explains the rapid growth of Kappa Carrageenan usage.

How do we evaluate the quality of Kappa Carrageenan?

Normally we see it in 3 dimensions: physical presence, chemical contents, and gel evaluation. Good quality Kappa Carrageenan has bright color with no strong odor, contains low level of chloride, and gels strongly.

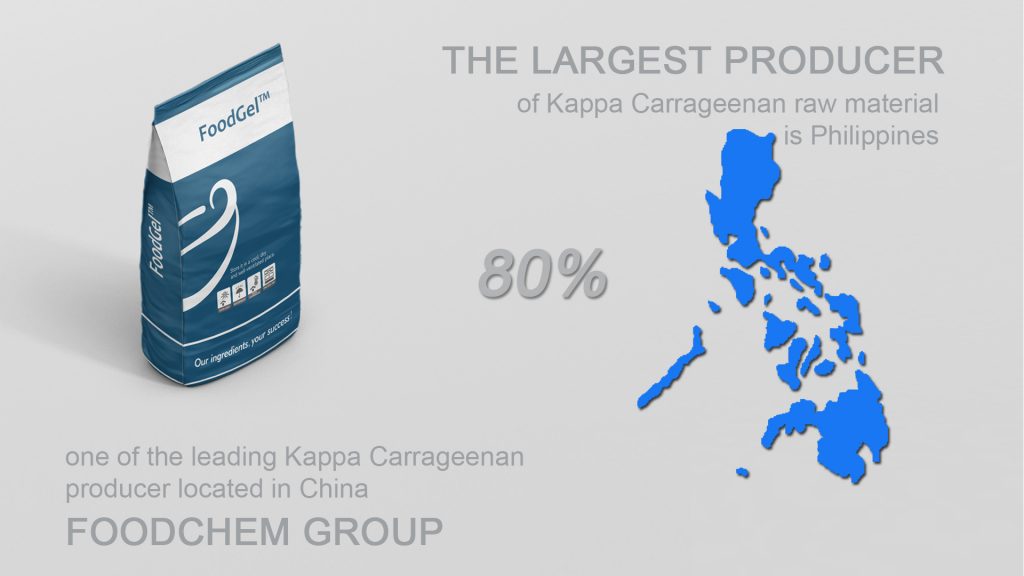

As of today, the largest producer of Kappa Carrageenan raw material is Philippines where supplies 80% of the world seaweed for industrial use, while China remain as the main exporter to global markets of Kappa Carrageenan. Foodchem Group is one of the leading gelatins, Kappa Carrageenan, collagen producer located in China with extensive experience. We supply high quality Kappa Carrageenan under the brand Foodgel™, includes refined and semi-refined Kappa Carrageenan both. We boost business excellence of our clients by providing cost friendly, high quality product in a lean & swift fashion and aim to be a significant link of the global food supply chain.

On top of bringing the best product there is, Foodchem Group will also keep updating its knowledge pool related to the latest, hottest discussing food ingredients like Kappa Carrageenan gelatin, collagen peptides or sugar substitute so that not only us, but also our clients, partners and friends may keep a close tab on the vibe of this business, thus, lays the foundation of our mutual success.